| SPINDLE | |

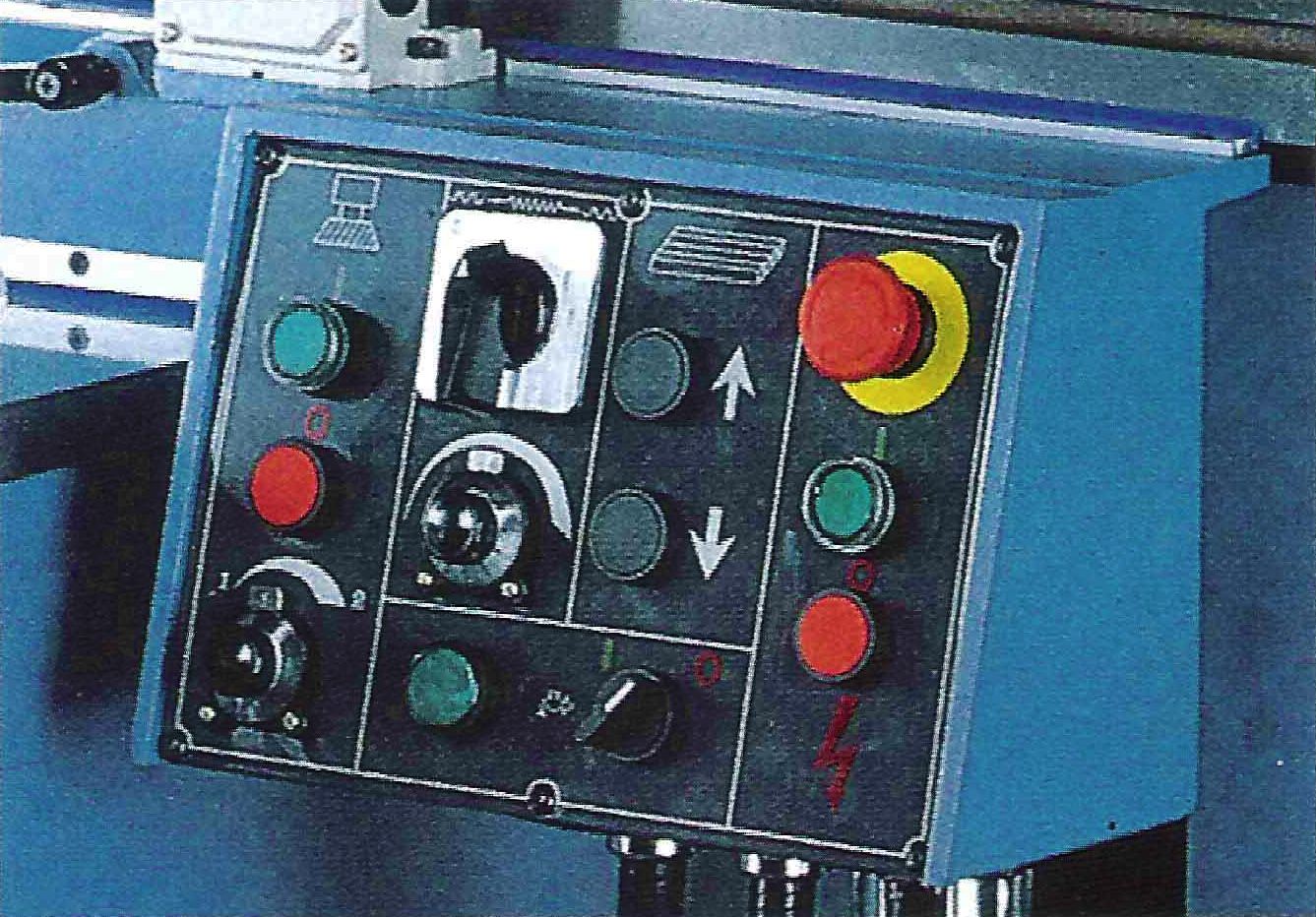

| Spindle speeds | 60-3600 RPM VARIABLE SPEED (Max. 4050RPM) |

| Spindle nose taper | NST & ISO 40 |

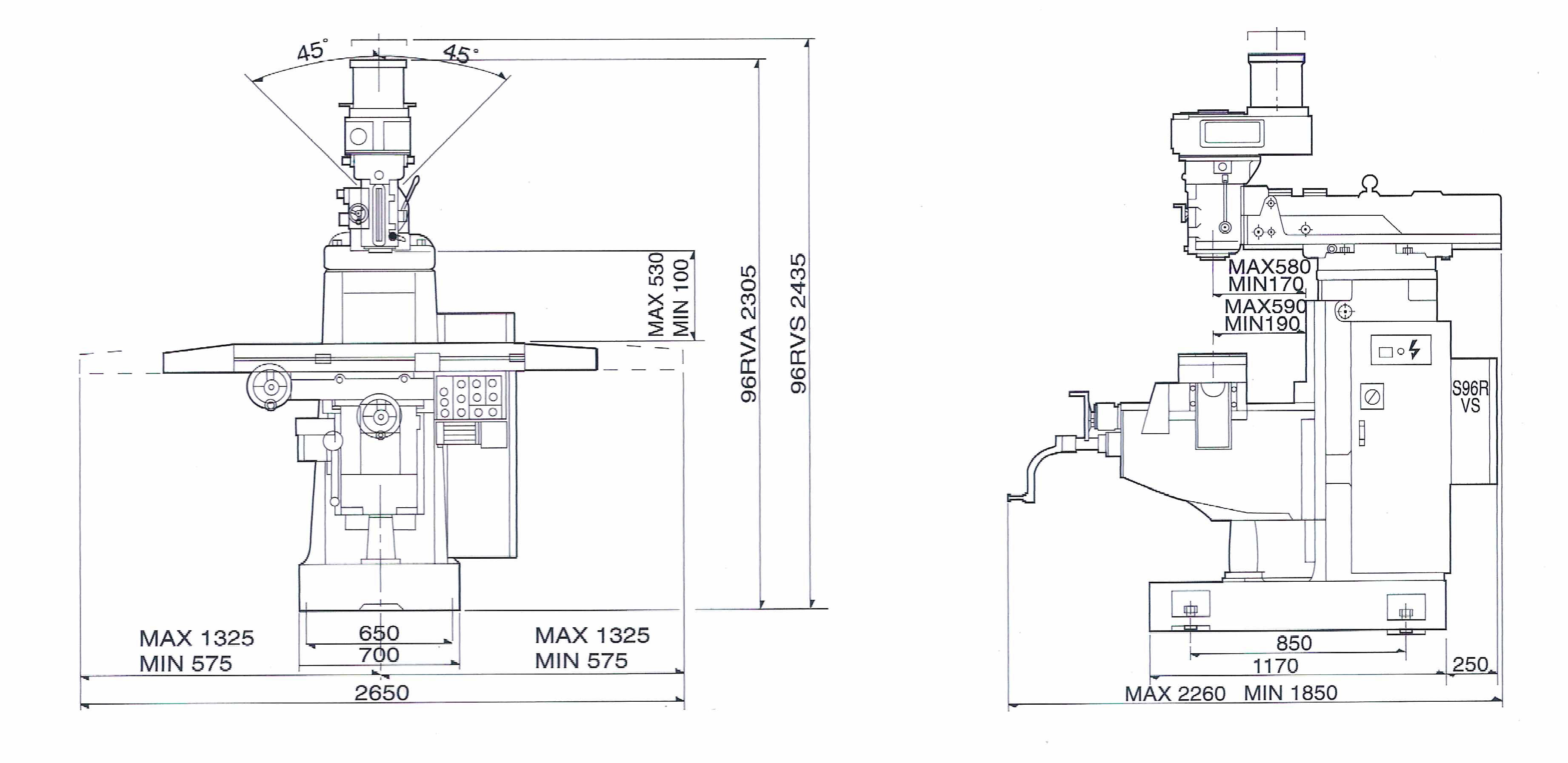

| Head tilt (R & L) | 45° (R&L) |

| Overarm travel | 410 mm |

| Quill travel | 140 mm |

| Distance from spindle nose to table | 0-530 mm |

| Distance from spindle center to column | 170-580 mm |

| Automatic spindle feed speed | 0.035 / 0.07 / 0.14 mm (PER REV.) |

| TABLE | |

| Table area | 1250 x 280 mm |

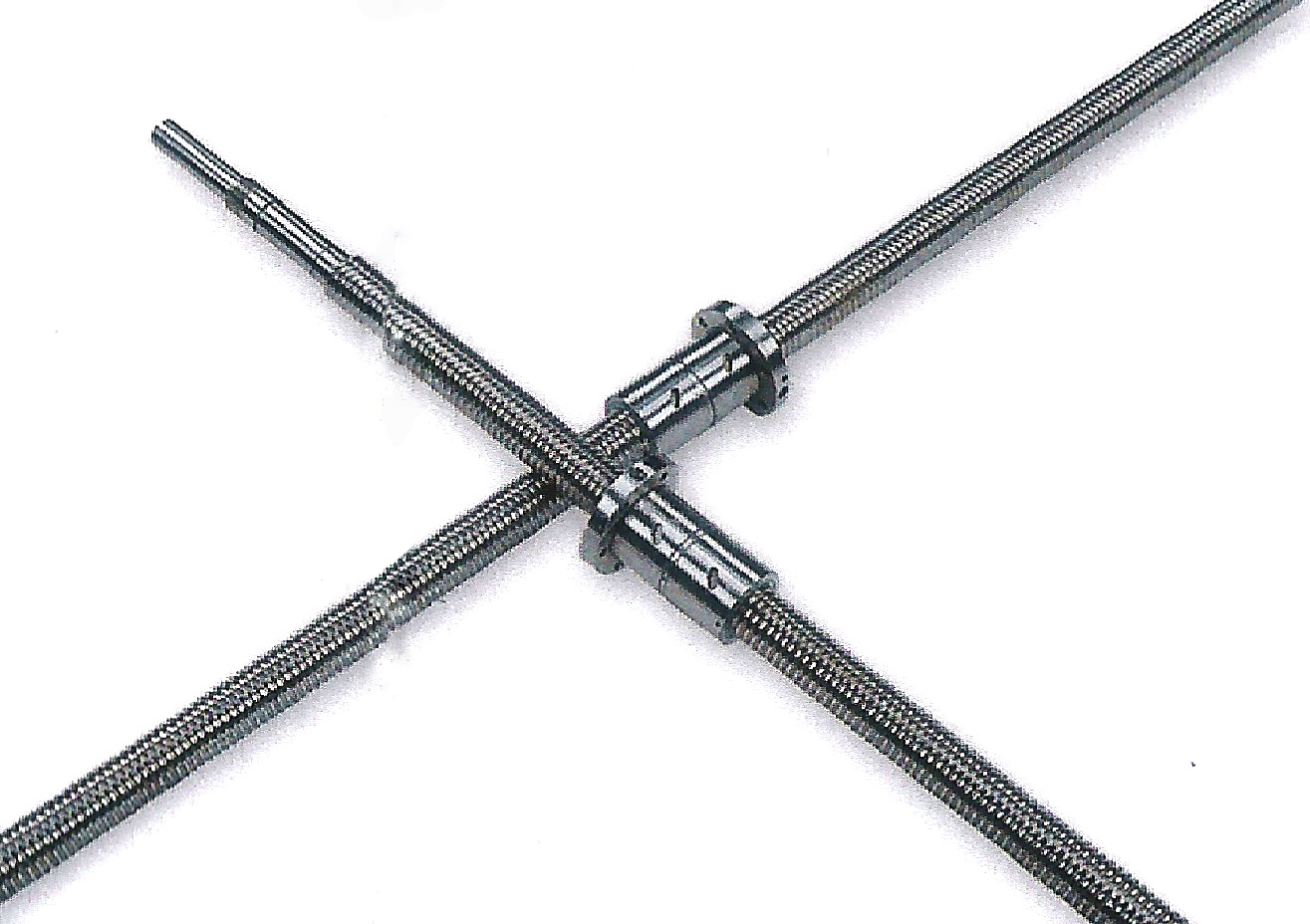

| Longitudinal travel | 750 mm |

| Cross travel | 400 mm |

| Vertical travel | 440 mm |

| T-slot (Width x No. x Distance) | 16 x 3 x 65 mm |

| Automatic lougitudinal travel | 0-1500 mm/min |

| Quick lougitudinal travel | 3500 mm/min |

| Quick vertical travel | 1150 mm |

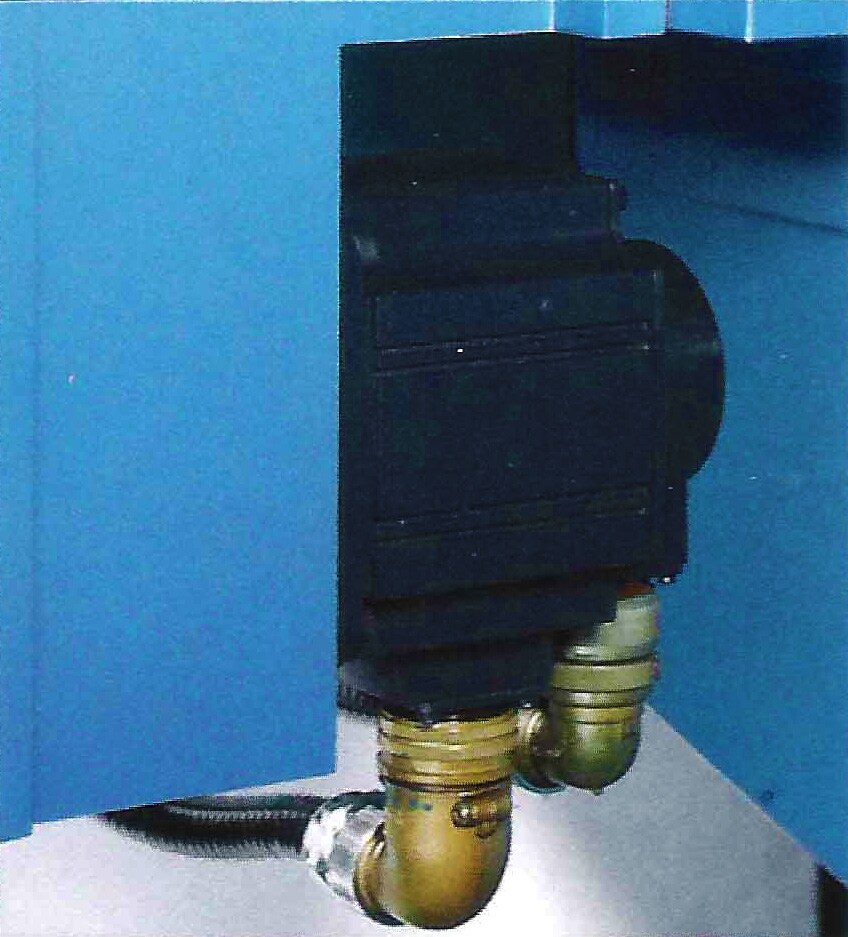

| MOTOR | |

| Spindle | 3.7 KW (5HP) VARIABLE SPEED MOTOR |

| Knee | 0.75 KW (1HP) |

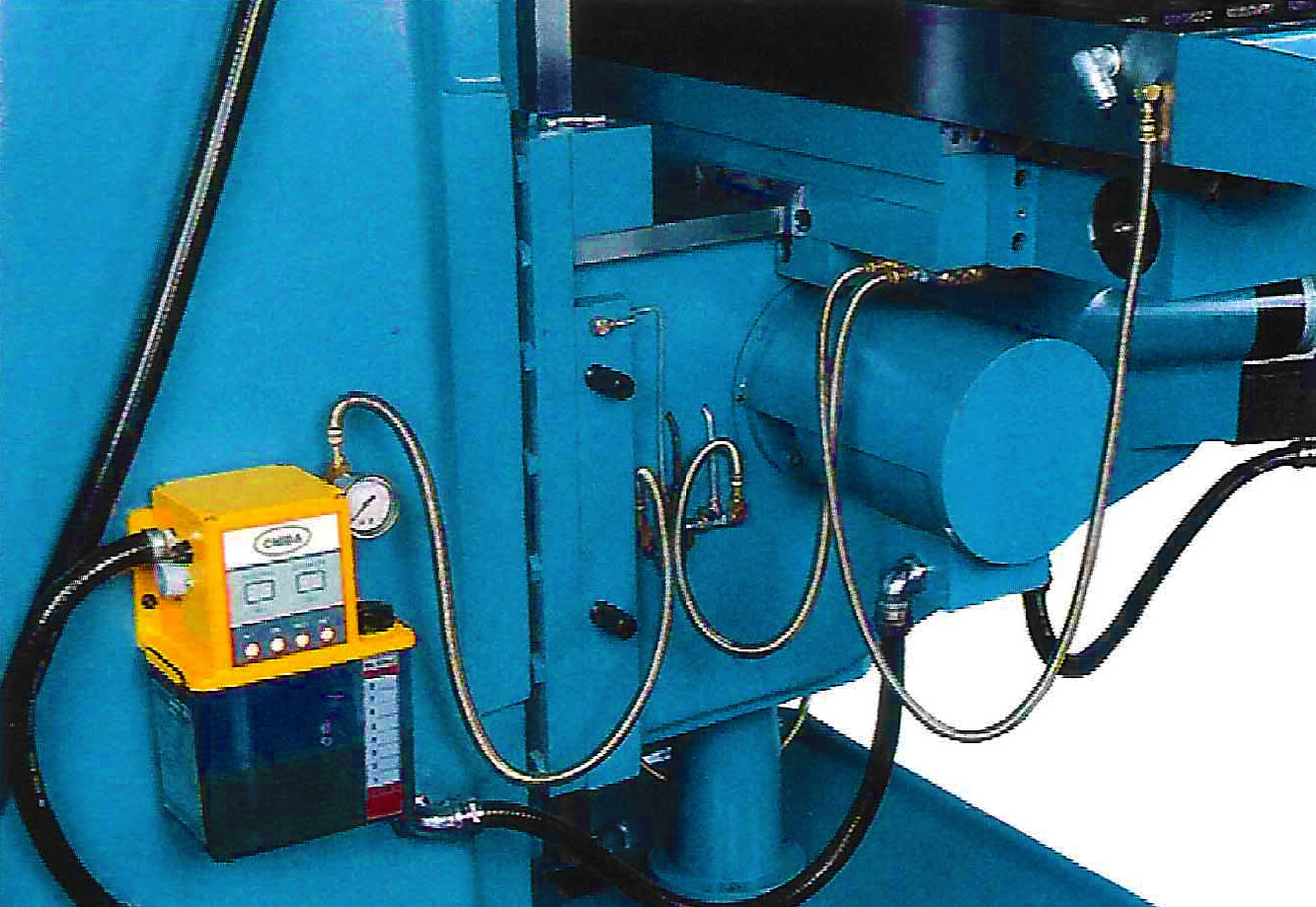

| Lubrication pump | 75 W |

| Magnetic pump | 13 W |

| PACKING | |

| Machine dimentions | 1900 x 2260 x 2305 mm |

| Packing dimentions | 1460 x 1920 x 2030 mm |

| N.W. | 2160 KG |

| G.W. | 2320 KG |

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.